- Eastbourne, East Sussex

- 01323 364 439

- Email M and M Electrical

- Mon-Sat: 8am - 5:30pm

- Emergency Call Out: Click to Call

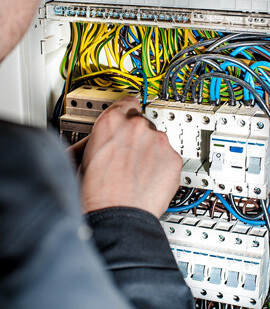

Fixed Installation Testing is the inspection and testing of the permanent electrical systems (circuits) within premises. It is an electrical survey carried out to ascertain if there are any faults present within the fixed electrical installation and also to check that the electrical installation complies with current electrical legislation.

M and M Electrical Services carry out fixed installation testing to BS7671 IEE (IET) Wiring Regulations standards. Our electrical engineers hold both City and Guilds 2381/2382 and 2391 electrical qualifications and are fully experienced in the inspection and testing of commercial, industrial and residential premises.

First and foremost we will liaise with you as to the purpose for the fixed installation testing and ascertain the extent of inspection and testing to be carried out. It is our aim to minimise disruption to your premises whilst at the same time provide a thorough and professional electrical testing service.

The routine inspection and testing of your fixed electrical installation, ensures compliance under the Health and Safety at Work Act 1974, the Electricity at Work Regulations 1989 and the Consumer Protection Act 1987. Electrical installation testing is also a common requirement for business and public premises insurance.

Following a visual inspection and verification of the entire electrical installation, the following test procedures are applied where appropriate, in order to ascertain the safety of electrical installation :

Upon completion of the electrical testing, a detailed Electrical Installation Condition Report (EICR) is supplied containing the following certification:

The engineer who carried out your testing will also talk through the results with you and explain if any remedial work is necessary in order to remedy an unsafe installation. If the electrical installation has any faults, they will be listed under the section of observations and recommendations and will be given one of the following codes:

Although we are pleased to carry out any remedial work required, you are free to choose to have the work completed by a qualified third party. We are fully insured to the value of £2m. Copies of our insurance details are available to clients upon request.

Our electrical testing prices for business premises are extremely competitive and start at just £18 per circuit.